By now, many have noticed the rapid rise of the cannabis industry. Have you ever wondered what’s happening behind the scenes? Let’s take a look.

With the legalization of both medical and recreational cannabis in many parts of the world, growers and producers, have been adopting innovative technologies to meet the increasing demand. Their advanced technologies and expertise are revolutionizing the cannabis industry to ensure efficient production and maintain high-quality standards.

In this article, we’ll take you on a journey through the world of cannabis production, exploring cutting-edge techniques and practices revolutionizing the industry. From modern cultivation methods to advanced extraction techniques, the cannabis industry constantly evolves to deliver higher-quality products more efficiently and sustainably.

As you read on, you’ll discover how hydroponic and aeroponic systems are changing how cannabis is grown, how LED lighting improves energy efficiency, and how automated climate control provides the perfect environment for optimal growth. We’ll also delve into precision dosing and packaging solutions, quality control, lab testing, and sustainable and eco-friendly practices that pave the way for the future of cannabis production technology.

Modern cultivation techniques

Today’s cultivation methods have truly transformed how we grow and harvest marijuana, making it easier than ever to produce high-quality buds. These modern techniques often rely on advanced technologies and controlled environments to optimize growth, yield, and potency. As a result, you can enjoy a more consistent and potent product, free of contaminants and pesticides.

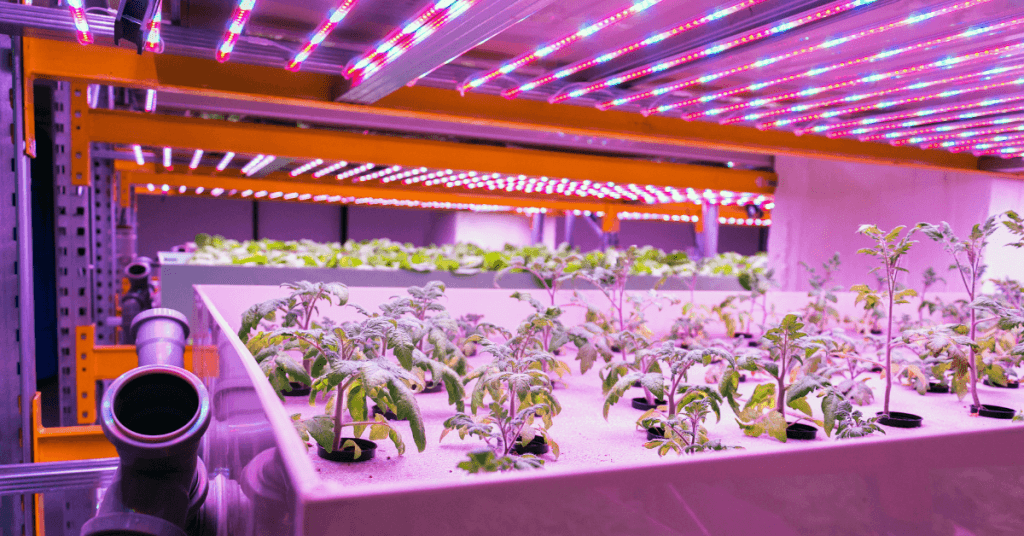

One such innovative cultivation method is light-emitting diode (LED) grow lights. These energy-efficient lighting systems provide a full light spectrum, closely mimicking the sun’s natural rays.

This allows for better control over the light exposure and intensity, resulting in faster growth, bigger yields, and increased potency.

Another technique that has gained popularity is vertical farming. This method allows more plants to be grown in a smaller space by stacking them vertically, thus increasing overall yield while reducing the required footprint. These advancements in cultivation techniques have paved the way for even more sophisticated growing methods, such as hydroponic and aeroponic systems. These systems allow for precise control over nutrient delivery and environmental conditions, further optimizing plant growth and quality.

So, as you enjoy the benefits of modern cannabis production, take a moment to appreciate the incredible technology and innovation that have made it all possible. And now, let’s dive into hydroponic and aeroponic systems to explore how they revolutionize cannabis growth.

Hydroponic and aeroponic systems

Hydroponic and aeroponic systems are dramatically transforming how plants are grown, making it easier than ever to cultivate high-quality cannabis in a controlled environment. These innovative technologies allow growers to optimize growth conditions, resulting in higher yields and faster harvests.

Hydroponic systems involve growing plants in nutrient-rich water instead of soil, while aeroponic systems suspend plants in the air and deliver nutrients via a fine mist.

- Nutrient Control: Hydroponic and aeroponic systems give you complete control over the nutrient mix, ensuring that your plants receive the ideal balance of nutrients for optimal growth. This level of precision eliminates the guesswork and trial and error typically involved in traditional soil-based cultivation.

- Reduced Water Use: Both hydroponic and aeroponic systems use significantly less water than traditional soil-based growing methods. This conserves a valuable resource and reduces the risk of overwatering, which can lead to root rot and other issues.

- Pest and Disease Management: By eliminating soil from the growing process, these systems reduce the likelihood of pests and diseases that thrive in soil. This means you can maintain a cleaner growing environment and minimize the need for pesticides, resulting in healthier plants and a safer end product.

These systems offer a range of benefits that contribute to more efficient and sustainable cannabis production. As you continue to explore the world of modern cannabis cultivation, you’ll discover other innovations that further enhance the process, such as LED lighting for energy efficiency.

This next technological advancement provides significant energy savings and allows for more precise control over the light spectrum and intensity, ensuring optimal growth conditions for your cannabis plants.

LED lighting for energy efficiency

It’s no secret that modern cannabis cultivation has embraced LED lighting, which not only significantly cuts energy costs but also allows growers to fine-tune the perfect light spectrum and intensity for thriving plants.

Traditional high-pressure sodium (HPS) and metal halide (MH) lights have been widely used, but they consume a lot of energy and generate excessive heat.

On the other hand, LED lights provide a more energy-efficient solution while offering a customizable light spectrum, which is essential for optimizing plant growth and maximizing yields.

LED lighting technology has advanced rapidly in recent years, making it possible for cannabis cultivators to optimize their grow rooms with previously unattainable precision. By adjusting the light spectrum and intensity, growers can mimic the natural sunlight that plants need during different stages of growth.

For example, during the vegetative stage, cannabis plants require more blue light, while the flowering stage requires a higher concentration of red light.

LED lights allow for this customization, enabling growers to provide the ideal conditions for each growth phase. Moreover, LED lights generate much less heat than traditional lighting systems, reducing the need for additional cooling equipment and lowering overall energy consumption.

This keeps utility bills in check and helps maintain a stable environment for plants, minimizing stress and promoting healthy growth.

As you continue to explore innovative technologies in cannabis production, consider how automated climate control can further optimize your grow room and contribute to consistently high-quality yields.

Automated climate control

Imagine being the conductor of your orchestra, directing every aspect of your grow room’s climate to create a harmonious symphony of optimal conditions for your plants. That’s precisely what automated climate control systems offer to cannabis cultivators.

By using cutting-edge technology, these systems monitor and regulate various environmental factors such as temperature, humidity, CO2 levels, and air circulation, ensuring that your cannabis plants grow in a stable and stress-free environment.

By automating these processes, you can focus on other aspects of your business while your plants flourish in their finely tuned-surroundings.

One of the primary benefits of automated climate control is maintaining a consistent environment, which is crucial for cannabis plants to achieve their full potential.

Sudden temperature, humidity, or CO2 fluctuations can lead to various issues such as mold, pests, or nutrient deficiencies.

Automated climate control systems continuously monitor these factors, making real-time adjustments to keep everything within the ideal range. This optimizes plant growth and yield and helps prevent problems that can be costly and time-consuming to remedy.

As the cannabis industry continues to evolve, so does the technology supporting it. Automated climate control systems are just one example of how innovation drives greater efficiency, consistency, and quality in cannabis production.

And as you master the art of orchestrating your grow room’s climate, you’ll be well-prepared to explore the next frontier in cannabis cultivation: advanced extraction methods.

Advanced Extraction Methods

As you delve into the world of advanced extraction methods, you’ll discover the intricate processes that transform your carefully cultivated plants into potent and pure products for consumers to enjoy. With innovative technologies constantly evolving, producers are now able to extract valuable compounds from cannabis in a more efficient and environmentally friendly manner.

Some of the most commonly used advanced extraction methods include:

- Supercritical CO2 extraction

- Uses carbon dioxide under high pressure and temperature to extract cannabinoids and terpenes.

- Results in a clean, solvent-free product

- Ethanol Extraction

- Utilizes food-grade ethanol as a solvent to dissolve cannabinoids and terpenes.

- Requires further purification to remove any remaining solvent.

The benefits of using advanced extraction methods are multifold. Not only do these techniques yield a cleaner and more potent end product, but they also minimize the risk of contamination from residual solvents.

Furthermore, advanced extraction methods allow for greater scalability, enabling cannabis producers to meet the ever-growing demand for high-quality cannabis products.

In addition to the safety and efficiency advantages, these methods can give producers more control over the final product’s cannabinoid and terpene profiles, allowing them to cater to specific consumer preferences and market trends.

As the cannabis industry continues to expand, producers must stay up-to-date with the latest extraction technologies to remain competitive and guarantee the quality of their products.

With that in mind, exploring the world of CO2 and solventless extraction techniques is essential, which offers even more innovative ways to extract valuable compounds from your cannabis plants.

CO2 and solventless extraction techniques

Delving into CO2 and solventless extraction techniques, we uncover cutting-edge methods that revolutionize how valuable compounds are extracted from cannabis plants.

CO2 extraction, or supercritical fluid extraction (SFE), employs carbon dioxide as a solvent to separate cannabinoids, terpenes, and other beneficial compounds from the plant material.

This process occurs at high pressure and temperature, turning CO2 into a supercritical fluid with both liquid and gas properties. The result is a clean, pure, and potent extract free of residual solvents and contaminants.

Solventless extraction techniques, on the other hand, do not use any chemical solvents. Instead, they rely on mechanical or physical means to separate the desired compounds from the plant material.

Some popular solventless extraction methods include dry sifting, ice water extraction, and rosin pressing. These methods utilize pressure, temperature, and filtration to collect trichomes, the resinous glands containing the highest cannabinoids and terpenes.

Solventless extracts are highly sought after by cannabis connoisseurs for their purity, rich flavor profiles, and full-spectrum benefits.

Both CO2 and solventless extraction techniques offer advantages for the cannabis industry, with each method catering to different product requirements and consumer preferences.

As the industry continues to evolve and innovate, the focus on clean, safe, and efficient extraction processes is paramount.

This commitment to quality and safety extends to precision dosing and packaging solutions, ensuring that the final products meet the highest consistency and reliability standards.

Precision Dosing and Packaging Solutions

Precision dosing and packaging solutions play a crucial role in the cannabis industry. It’s fascinating to learn that the global cannabis packaging market is expected to reach $5.2 billion by 2026, highlighting the demand for reliable and efficient systems.

As the industry evolves, manufacturers invest in innovative technologies to ensure accurate dosing and maintain product integrity throughout the supply chain. This enhances the consumer experience and complies with the stringent regulations governing cannabis production and distribution.

In recent years, several advanced solutions have emerged to meet the industry’s unique precision dosing and packaging requirements. Some of the key innovations include:

- Automated filling machines that ensure accurate and consistent dosing of cannabis products, such as oils, tinctures, and edibles

- Child-resistant packaging solutions that meet regulatory standards while preserving product quality and shelf life

- Tamper-evident packaging designs that protect against unauthorized access and maintain a secure chain of custody

- Advanced labeling systems that provide essential product information, traceability, and compliance with regulatory requirements

As more companies adopt these innovative technologies, the cannabis industry becomes increasingly sophisticated and professional.

This focus on precision dosing and packaging solutions ensures a safe and enjoyable consumer experience and paves the way for further advancements in the sector.

The next area where innovation significantly impacts is quality control and lab testing, which are essential for maintaining the highest standards of product safety and efficacy.

Quality Control and Lab Testing

It’s no secret that quality control and lab testing are integral to the success of the cannabis industry. With cutting-edge advancements in this field, we’re witnessing a whole new level of safety and efficacy for consumers.

As a consumer, you can now have confidence that your products are potent and free from harmful contaminants.

Technological innovations have allowed for the development of state-of-the-art laboratories that can accurately test for potency, terpenes, pesticides, heavy metals, and other potential hazards, ensuring that you’re getting the highest-quality cannabis products available.

These advanced testing facilities utilize sophisticated instruments like high-performance liquid chromatography (HPLC), gas chromatography-mass spectrometry (GC-MS), and inductively coupled plasma mass spectrometry (ICP-MS) to provide accurate results.

HPLC is used to determine the potency of cannabinoids, while GC-MS is employed to identify terpenes and residual solvents. ICP-MS is a powerful tool for detecting heavy metals and other trace elements.

The use of these technologies not only guarantees the safety and quality of your cannabis products but also allows producers to fine-tune their formulations to create targeted, consistent experiences for you, the consumer.

As the cannabis industry continues to grow and evolve, quality control and lab testing will remain at the forefront, ensuring you have access to the safest, most effective products.

These technological innovations contribute to the industry’s overall success and pave the way for adopting sustainable and eco-friendly practices that will benefit both the consumer and the planet.

Solventless Extraction: The Rosin Press Method

In a rapidly growing industry that is constantly striving for purity and potency, solventless extraction methods have gained popularity due to their ability to produce clean and high-quality cannabis concentrates without the use of potentially harmful solvents. One such method is the rosin press extraction.

The rosin press method uses a combination of heat and pressure to extract cannabinoids and terpenes from the cannabis plant. In essence, the cannabis plant material is placed between two heated plates and then pressure is applied. This process results in a sticky and resinous substance known as rosin.

One of the leading tools in this space is the Triminator Rosin TRP Stack. This advanced rosin press is designed to optimize yield, efficiency, and quality, making it an essential piece of equipment for any serious cannabis producer.

Equipped with patent-pending technology, the Triminator Rosin TRP Stack allows for precise control over heat and pressure, ensuring the most effective extraction process. This device’s capabilities include eight tons of pressure and dual heat plates, allowing you to process large quantities of cannabis efficiently.

Moreover, it has been designed with user safety and comfort in mind. The intuitive design, including features like an ergonomic press handle and safety start button, ensures ease of use without compromising on safety.

By using a high-quality rosin press like the Rosin TRP Stack, cannabis producers can offer a clean, solvent-free product that retains the plant’s beneficial compounds, satisfying the demands of discerning consumers who value purity and potency in their cannabis products.

This is just another example of how technological advancements are transforming the cannabis industry, enhancing both production efficiency and product quality. As we continue to explore the world of modern cannabis production, we’ll see more innovative solutions that are sure to push the industry to even greater heights.

Sustainable and eco-friendly practices

As you explore the world of cannabis, you might be pleasantly surprised to discover the industry’s growing commitment to sustainable and eco-friendly practices. With the increasing demand for cannabis products, cultivators and businesses seek innovative ways to reduce their environmental footprint and contribute to a greener future.

From energy-efficient cultivation methods to waste reduction and management, the cannabis industry is making strides in adopting sustainable practices that benefit both the environment and consumers.

One such practice gaining popularity is using LED lighting in indoor cannabis cultivation. Compared to traditional high-pressure sodium (HPS) lights, LED lights consume less energy and produce less heat, reducing the need for energy-intensive cooling systems.

Additionally, many cultivators are implementing water conservation techniques, such as collecting rainwater for irrigation and using closed-loop systems that recycle water back into the growing process.

These practices save water and reduce the amount of harmful runoff that can pollute local water sources.

Moreover, the industry increasingly turns to organic and regenerative agriculture practices focusing on soil health, biodiversity, and ecosystem preservation.

Cultivators can use natural pest control methods and cover crops to minimize harmful chemicals and reduce soil erosion.

These eco-friendly practices are essential for the long-term success and sustainability of the cannabis industry.

As we look ahead, the future of cannabis production technology will continue to prioritize and innovate sustainable solutions that protect our planet and support the growing demand for high-quality cannabis products.

The Future of Cannabis Production Technology

We’re bound to see even more advancements in sustainable methods and cutting-edge technologies within the cannabis industry, shaping a greener and brighter future for all.

As cannabis production expands globally, so will the need for innovative solutions that address environmental concerns, optimize efficiency, and improve the overall quality of cannabis products.

Enhanced plant genetics, advanced cultivation techniques, and the seamless integration of artificial intelligence and automation will likely characterize the future of cannabis production technology.

One area of focus in the future of cannabis production technology is the development of genetically modified cannabis strains that are better suited for specific climates, resistant to pests and diseases, and more efficient in resource utilization. T

his will enable producers to grow high-quality cannabis with minimal environmental impact.

Furthermore, advanced cultivation techniques like vertical farming, aeroponics, and hydroponics will become more widespread, allowing for higher yields in smaller spaces and reducing the need for harmful chemicals and excessive water consumption.

As the industry progresses, we expect greater reliance on artificial intelligence and automation to streamline cannabis production processes.

From smart sensors that monitor and adjust growing conditions in real time to automated harvesting and processing equipment, these technologies will help producers increase efficiency, reduce labor costs, and minimize waste.

Blockchain technology may also play a role in improving transparency and traceability within the cannabis supply chain, ensuring that consumers have confidence in the products they purchase.

The future of cannabis production technology promises to be both environmentally responsible and economically viable, setting a new standard for the industry.

More to come…

So, there you have it, folks. You’ve peeked behind the curtain of cannabis production, witnessing the cutting-edge innovations that make it all possible.

Who knew that growing a plant could be so sci-fi?

Just remember, next time you’re admiring your perfectly dosed edible or marveling at the purity of your vape pen, take a moment to appreciate the technological wizardry that’s gone into creating your magical experience.

After all, it’s not just Mother Nature doing all the work these days.